Product Introduction

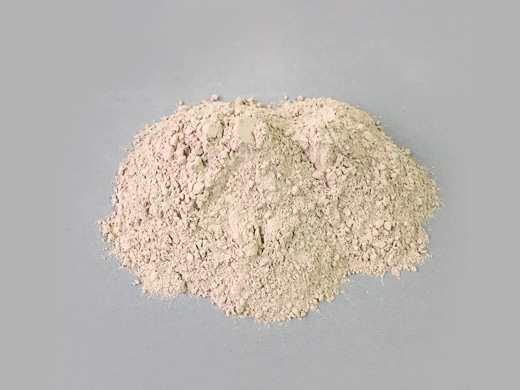

High alumina mortar is mainly made of high grade bauxite and other additives. The Al2O3 content of it is from 55% to 75%.

Features

1.Good plasticity and convenient construction.

2.High bonding strength.

3.Strong corrosion resistance.

4.High refractoriness.

5.Good slag resistance.

6.Good heat-stripping property.

Application

It is mainly used for laying, bonding and jointing of high alumina bricks in the construction of furnaces or equipment.

Technical Data

| Item |

Common Type |

Phosphate Bonded Type |

| |

LN-55A |

LN-65A |

LN-75A |

LN-85A |

LN-55B |

LN-65B |

LN-75B |

LN-85B |

| Al2O33 (%) ≥ |

55 |

65 |

75 |

85 |

55 |

65 |

75 |

85 |

| Refractoriness(℃) ≥ |

1770 |

1790 |

1790 |

1790 |

1770 |

1790 |

1790 |

1790 |

| Cold Flexural Strength (Mpa) ≥ |

110℃ After Drying |

1.0 |

1.0 |

1.0 |

2.0 |

2.0 |

2.0 |

2.0 |

2.0 |

| |

1400℃*3h After Burning |

4.0 |

4.0 |

4.0 |

-- |

6.0 |

6.0 |

6.0 |

-- |

| |

1500℃*3h After Burning |

-- |

6.0 |

-- |

6.0 |

| Refractoriness Under Load 2%(℃) ≥ |

-- |

1300 |

1400 |

1400 |

1600 |

| Permanent Linear Change (%) |

1400℃*3h After Burning |

1-5 |

1-5 |

1-5 |

-- |

1-5 |

1-5 |

1-5 |

-- |

| |

1500℃*3h After Burning |

-- |

1-5 |

-- |

1-5 |

| Bonding Time (Min) |

1-3 |

| Particle Size (%) |

-0.1mm |

100 |

| |

+0.5mm |

2 |

-- |

| |

-0.074mm |

50 |

40 |

50 |

40 |