Product Introduction

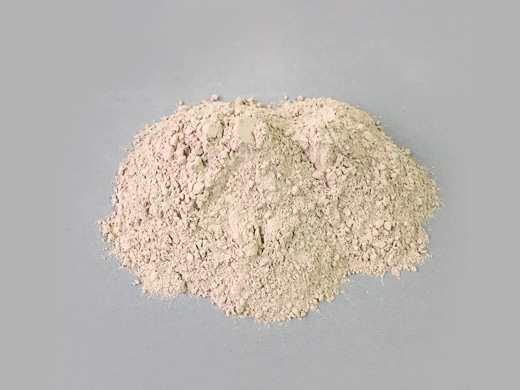

Fireclay mortar is also known as joint filler. It is composed of a certain particle ratio of refractory powder, binder and additive, pour water or liquid binder to tune into a paste. Fireclay mortar is one of the most common used refractory mortar which is as flint clay clinker as base material, binder adopts mild-clay or chemical bond.

Features

1.High refractoriness.

2.Fast bonding speed.

3.High cold flexural strength.

4.Granularity standard.

Application

Fireclay mortar is mainly used for jointing and repair of blast furnace, hot blast furnace, coke oven, soaking pit furnace, heat exchanger, boiler and other masonry of high quality clay bricks industrial furnace.

Technical Data

| Item |

Fireclay Mortar |

| NN-30 |

NN-38 |

NN-42 |

NN-45A |

NN-45B |

| Al2O3(% ) ≥ |

30 |

38 |

42 |

45 |

45 |

| Refractoriness (℃ ) ≥ |

1630 |

1690 |

1710 |

1730 |

1730 |

| Cold Flexural Strength (Mpa) ≥ |

110 ℃After Drying |

1.0 |

2.0 |

| 1200℃ *3hAfter Burning |

3.0 |

6.0 |

| Refractoriness Under Load 2.0% (°C) ≥ |

-- |

1200 |

| Permanent Linear Change % |

1200℃*3hAfter Burning |

1-3 |

-- |

| 1300℃ *3hAfter Burning |

-- |

1-5 |

| Bonding Time Minutes |

1-3 |

| Particle Size % |

-0.1mm |

100 |

| +0.5mm |

2 |

| -0.074mm |

50 |

| Remarks: A represents common fireclay mortar, B represents phosphate-bonded fireclay mortar. |