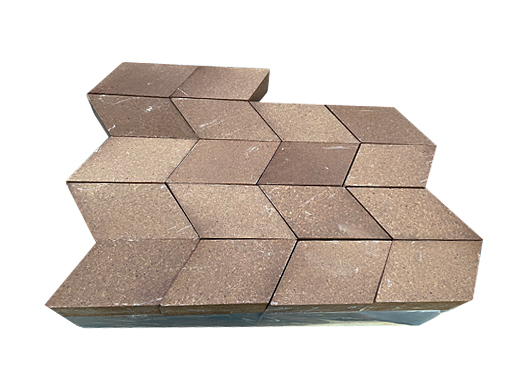

Product Introduction

Silicon Carbide Brick is a kind of refractory product mainly made of SiC, and the silicon carbide content is 72%~99%. Generally, it’s made by the black silicon carbide( content above 96%).

Application

Silicon carbide bricks can be used for metallurgical steel cylinder lining, nozzle, plug, blast furnace bottom ,non-ferrous metal smelting still, electrolytic cell side wall, smelting metal crucible, silicate industry furnace sheds and flame-proof materials, oil and gas generators in the chemical industry, organic waste combustion furnaces and aluminum refining furnace linings, etc.