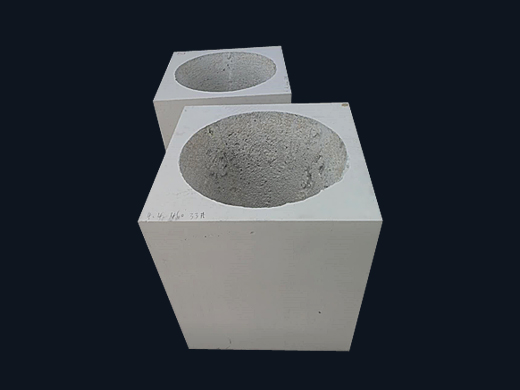

Product Introduction

Silica brick is an acid refractory material composed of tridymite, cristobalite and a small amount of residual quartz and glass phase. Silica bricks have good resistance to acid slag erosion. The refractoriness under load is as high as 1640~1670℃, and the volume is relatively stable under high temperature for long-term use.

Features

1.Good resistance to acid slag erosion.

2.High strength at high temperature.

3.Little dimensional change when using at high temperature for a long time.

Application

It is mainly used for the chamber and combustor of coke oven, regenerator chamber and cinder chamber of steelmaking open hearth furnace, soaking pit, refractory material of glass melting furnace, vault and other load-bearing parts of ceramic kiln .It is also used for high temperature load bearing parts of hot blast furnace and roof of acid open hearth furnace.

Technical Data

| Item |

KN |

KD |

KS |

Testing In Accordance With |

|

Regenerator |

Boiler Wall |

Carbonization Chamber Bottom |

|

Boiler Wall |

|

Oven Roof |

|

ChemicalComposition |

SiO2 |

% μG |

≥94.5 |

≥95.0 |

DIN51070 |

|

σ |

1.0 |

1.0 |

Part 26 |

|

Al2O3 |

% μG |

≤2.0 |

≤1.5 |

DIN51070 |

|

σ |

0.3 |

0.3 |

Part 36 |

|

Fe2O3 |

% μG |

≤1.0 |

≤1.0 |

DIN51070 |

|

σ |

0.2 |

0.2 |

Part 56 |

|

CaO |

% μG |

≤3.0 |

≤3.0 |

DIN51070 |

|

σ |

0.35 |

0.35 |

Part 76 |

|

Na2O+K2O |

% μG |

≤0.35 |

≤0.35 |

DIN51070 |

|

σ |

0.02 |

0.02 |

Part 86 |

|

Residual Quartz Content1) |

Raw Materials Type A(Coarse Crystalline) |

% μG |

As Per Mutual Agreement |

(2) |

|

σ |

6.0 |

|

xmax |

|

|

Raw Materials Type B(Crypto Crystalline) |

% |

1.5 |

- |

|

0.5 |

- |

|

Cold Compressive Strength |

N/mm2μG |

≥282) |

≥35 |

≥45 |

DIN51067 Part 1 |

|

σ |

10 |

10 |

10 |

|

xmin |

20 |

25 |

30 |

|

Apparent Porosity |

% μG |

≤24.5 |

≤22.0 |

≤22.0 |

DIN51056 |

|

σ |

1.3 |

1.3 |

1.3 |

|

Refractoriness Under Load Initial Temperature ta |

℃ μG |

≥1640 |

≥1650 |

DIN51064 |

|

σ |

25 |

25 |

|

Refractoriness Under Load T0.5℃ (Differential Method) |

℃ μG |

According to Agreements |

DIN51053 |

|

σ |

Part 1 |

|

Compressive Creep 3) |

% μG |

≤0.12 |

- |

DIN51053Part 2 |

|

σ |

0.05 |

|

% μG |

≤0.35 |

|

σ |

0.1 |

- |

|

|

Refractoriness 4) |

SK μG |

≥170(SK31)5) |

- |

- |

DIN51063Part 1 |

|

σ |

2(SK1)5) |

|

Average Thickness Loss |

mm μG |

- |

- |

≤4.5 |

DIN52108 |

|

σ |

0.1 |