Product Introduction

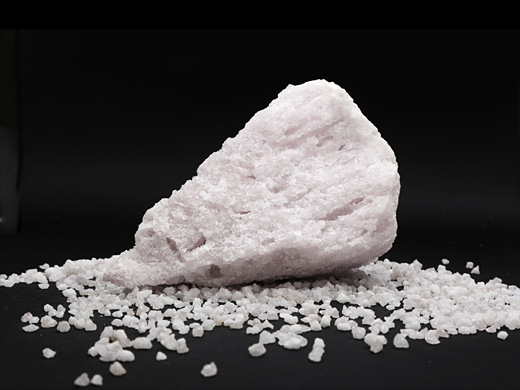

Calcined bauxite is produced by sintering high-alumina bauxite in rotary, round or shaft kilns at high temperatures. This process of calcining (heating) bauxite in kilns removes moisture and gives calcined bauxite its high alumina content.

Features

1. Hardness 3 to 8 or higher.

2. High bulk density.

3. Dense structure.

4. Low water absorption.

5. Good resistance to slag and alkali.

6. High strength.

7.High refractoriness.

Application

It is mainly used in aluminum smelting industry, precision casting industry, refractory product manufacturing, cement industry, abrasive material manufacturing, ceramic industry and chemical industry.

Technical Data

|

TYPE PROPERTIES |

RKB-88 |

RKB-86 |

RKB-80 |

|

Al2O3 |

88%min |

86%min |

80%min |

|

SiO2 |

6%max |

8%max |

14%max |

|

Fe2O3 |

2%max |

2.3%max |

2.5%max |

|

K2O+ Na2O |

0.30%max |

0.40%max |

0.40%max |

|

Ti2O3 |

3.8%max |

4.0%max |

4.0%max |

|

Bulk density |

3.20 g/cm3min |

3.15g/cm3min |

3.00g/cm3min |

|

Sizes |

0-50/0-25/8-5/5-3/3-1/1-0mm |

|

3x6/6x8/8x14/14x28/28x48/-48mesh |

|

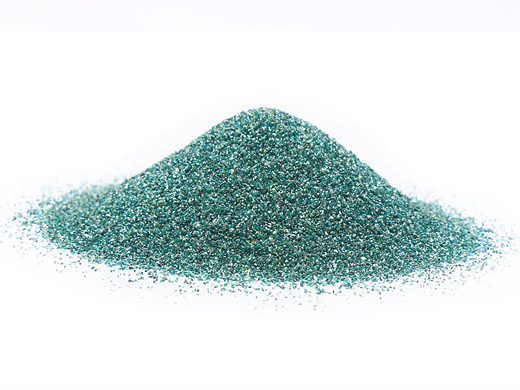

Fines |

-100/-200/-325mesh |

|

Test standard |

GB/T6900.1 |