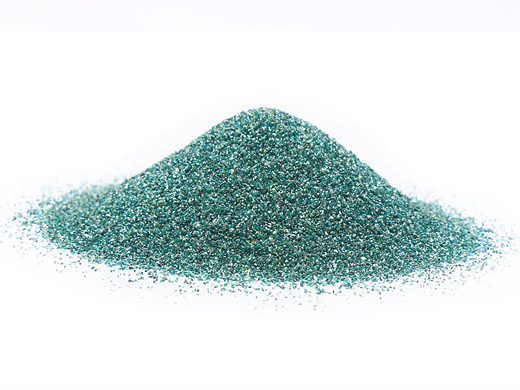

Product Introduction

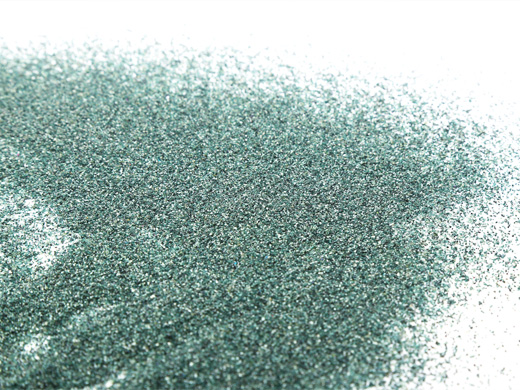

Silicon carbide is made by high temperature smelting of raw materials such as quartz sand, petroleum coke (or coal coke), wood chips (salt is needed to produce green silicon carbide) in a resistance furnace. At present, silicon carbide is divided into black silicon carbide and green silicon carbide, both of which are hexagonal crystals, with a specific gravity of 3.20-3.25 and a microhardness of 2840-3320kg/mm2.

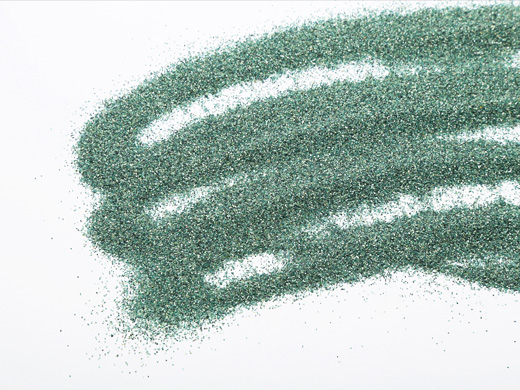

Application

Mainly used to manufacture functional ceramics, advanced refractories, abrasives and metallurgical raw materials.