Product Introduction

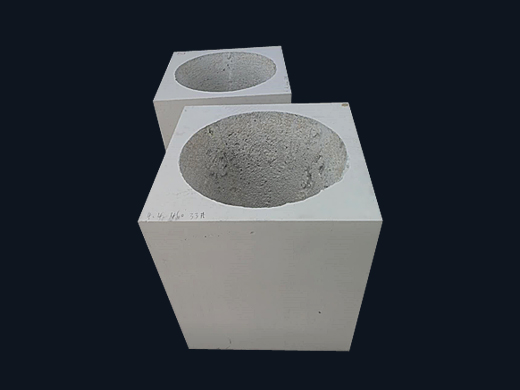

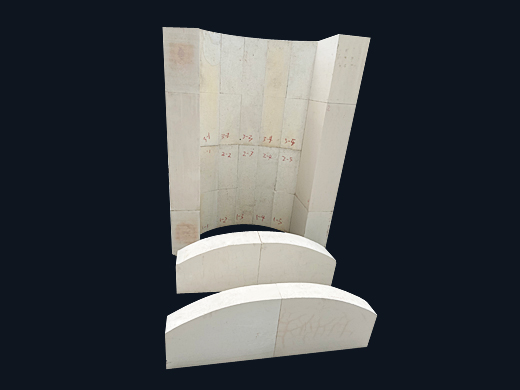

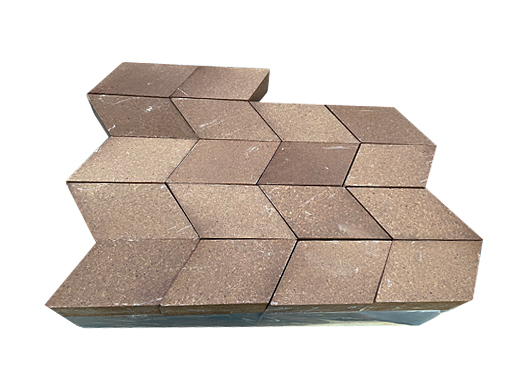

AZS block is also called fused zirconia corundum brick which contains Al2O3-ZrO2-SiO2. The fused cast AZS block is made of pure alumina powder and zircon sand (consisting of 65% zirconia and 34% SiO2). After the alumina powder and zircon sand are melted in an electric furnace, they are cast into various molds and cooled down to become white solids. Since the content of zirconia is between 33% and 41%, the fused cast AZS blocks are divided into three types: AZS-33#, AZS-36# and AZS-41#.