-

Refractory Brick

- Fire Clay Brick

- Zircon Block

- High Alumina Brick

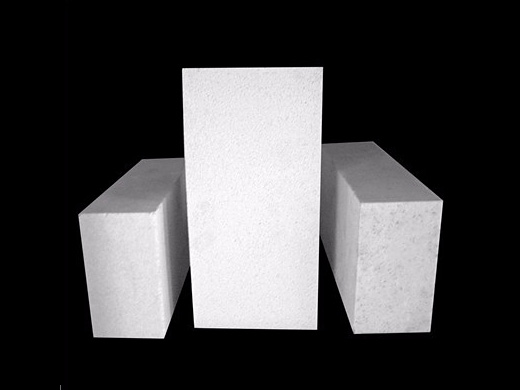

- Corundum Brick

- Mullite Brick

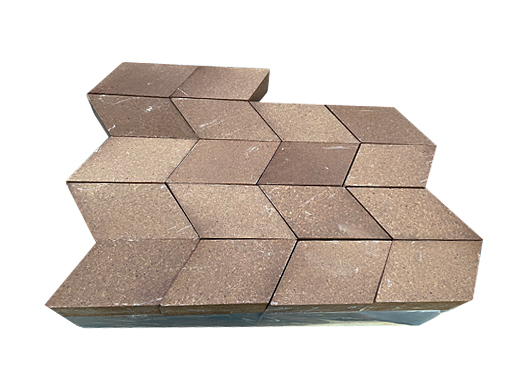

- Magnesia Chrome Brick

- Fused Rebonded Magnesia Chrome Brick

- Spinel Brick

- Silica Brick

- Fused Silica Brick

- Sillimanite Brick

- Silicon Mullite Brick

- Andalusite Brick

- Anchor Brick

- Acid Proof Brick

- Silicon Carbide Brick

- Magnesia Brick

- Fused Cast AZS Block

- Insulation Brick

- Monolithic Refractories

- More Refractories

- About Us

- News

- References

- Contact Us