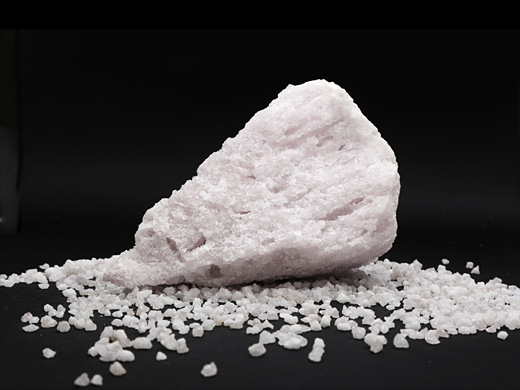

Product Introduction

Fused Zirconia Mullite is made by the fusion of high-quality zirconia sand and industry alumina powder in the electric arc furnace. Adding zirconium can improve the chemical resistance, heat shock resistance and reduce the expansion coefficient of mullite.

Features

1.Good chemical resistance.

2.Good thermal shock resistance.

3.Low expansion coefficient.

Application

Zirconium mullite is mainly used for new-type steel casting slides, sizing nozzles and shrouds of continuous casting ladle, and key parts of glass furnaces.

Technical Data

| Type |

Guaranteed Value |

Typical Value |

| Al2O3 |

44-48% |

45.8% |

| ZrO2 |

35-39% |

36.5% |

| SiO2 |

15.5-19.5% |

17.1% |

| Fe2O3 |

0.2%max |

0.14% |

| Mullite Phase |

60-65% |

| Baddeleyite Phase |

30-33% |

| Corundum Phase |

5%max |

| Glass Phase |

5%max |

| Bulk Density |

3.6g/cm3 min |

| Apparent Porosity |

3%max |

| Sizes |

0-50/8-5/5-3/3-1/1-0mm |

| Fines |

-100/-200/-325mesh |

| Test standard |

GB/T21114-2007, GB/T2999-2002 |