|

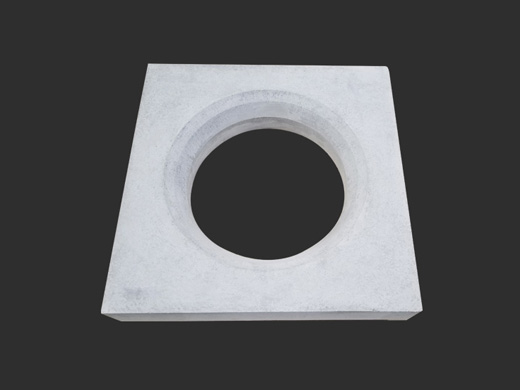

New type pre-cast oven door |

Traditional oven door |

|

Easy to installThe fastening bolts have been inserted in the precast. The precast oven door is clamped to the door structure directly by that bolts. |

The oven door installation is very complicated. |

|

The oven door is more air impermeability.The new type oven door consists of 6 or 7 precast refractory glazing crystalline ceramic refractory surface.The whole oven door exist 5 or 6 joints. |

Traditional oven door has more joints. The joints are easy to become bigger owing to long time mechanical operation.The air impermeability and insulating ability is worse. Heat loss, gas leakage and environment pollution are more serious. |

|

Crystalline ceramic refractory glaze have high refractoriness, good bonding performance and malleability, good thermal shock resistance. During the operation, the glaze have good spalling resistance under rapid variation of temperature. |

The raw materials of traditional door don’t have good mechanical strength and thermal shock resistance. |

|

Long-life |

Short-life |

|

The maintenance times and costs are reduced, and the labor cost is decreased 70%. |

Frequent repair and maintenance cost is high. |

|

Energy-saving and environment-friendlyGood heat insulationLess heat lossImprove the carbonation rate |

Energy consumption and environment pollutionGas leakageYellow smokeHeat dissipation |